This month we'd like to feature a fantastic Masters Research Project 3D animation by recent Biomedical Communications graduate Katrina Hass MScBMC, who worked with trauma surgeon Dr. Joao B. Rezende Neto MD, PhD, FRCSC, FACS to demonstrate a new surgical invention: the "Liver Airbag".

What follows is a description of her experience collaborating with the content expert Dr. Rezende-Neto. Specifically, she'll discuss some of the challenges she faced in communicating this topic visually, and her process of designing a visual solution to address these challenges.

Objectives

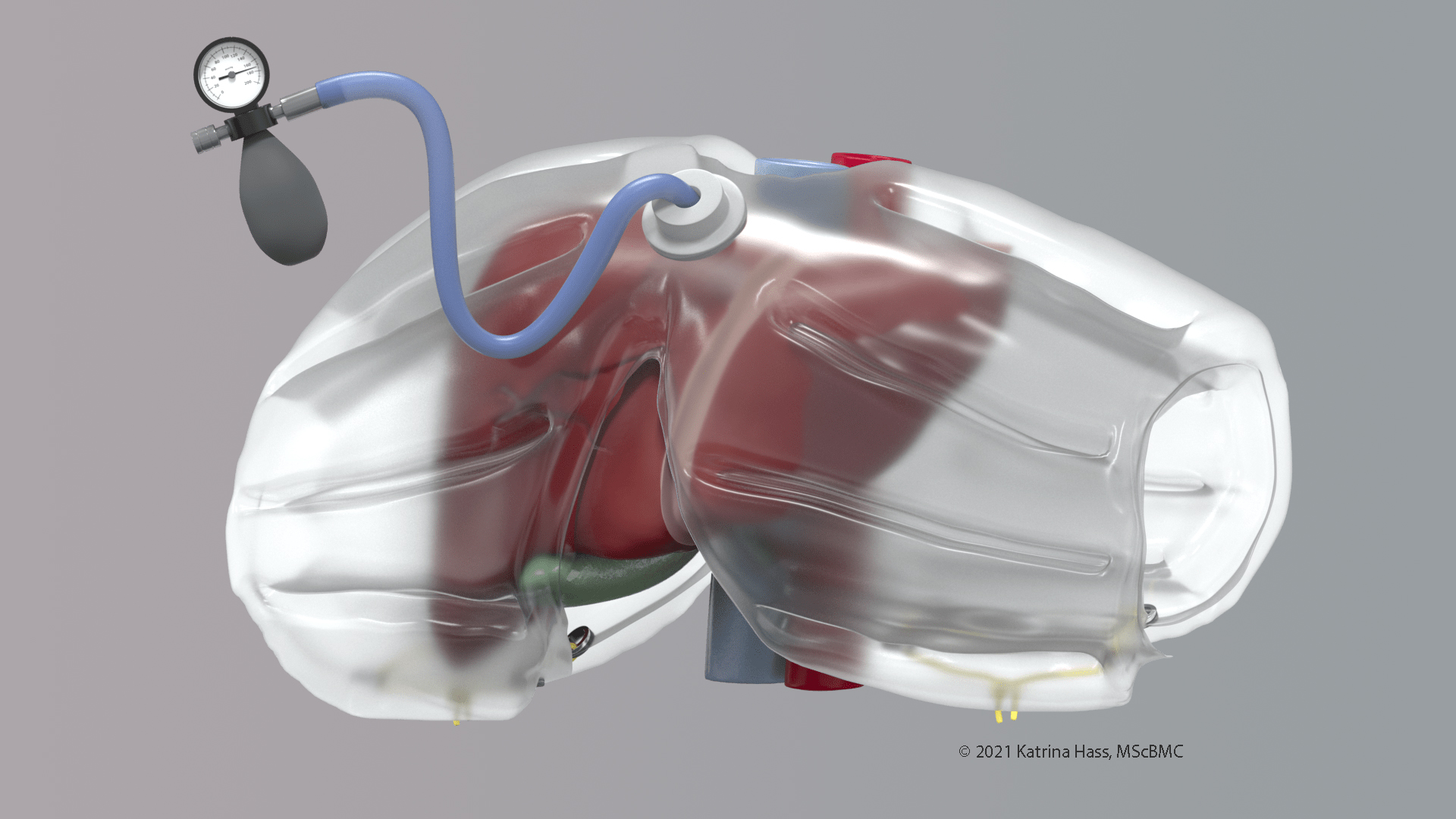

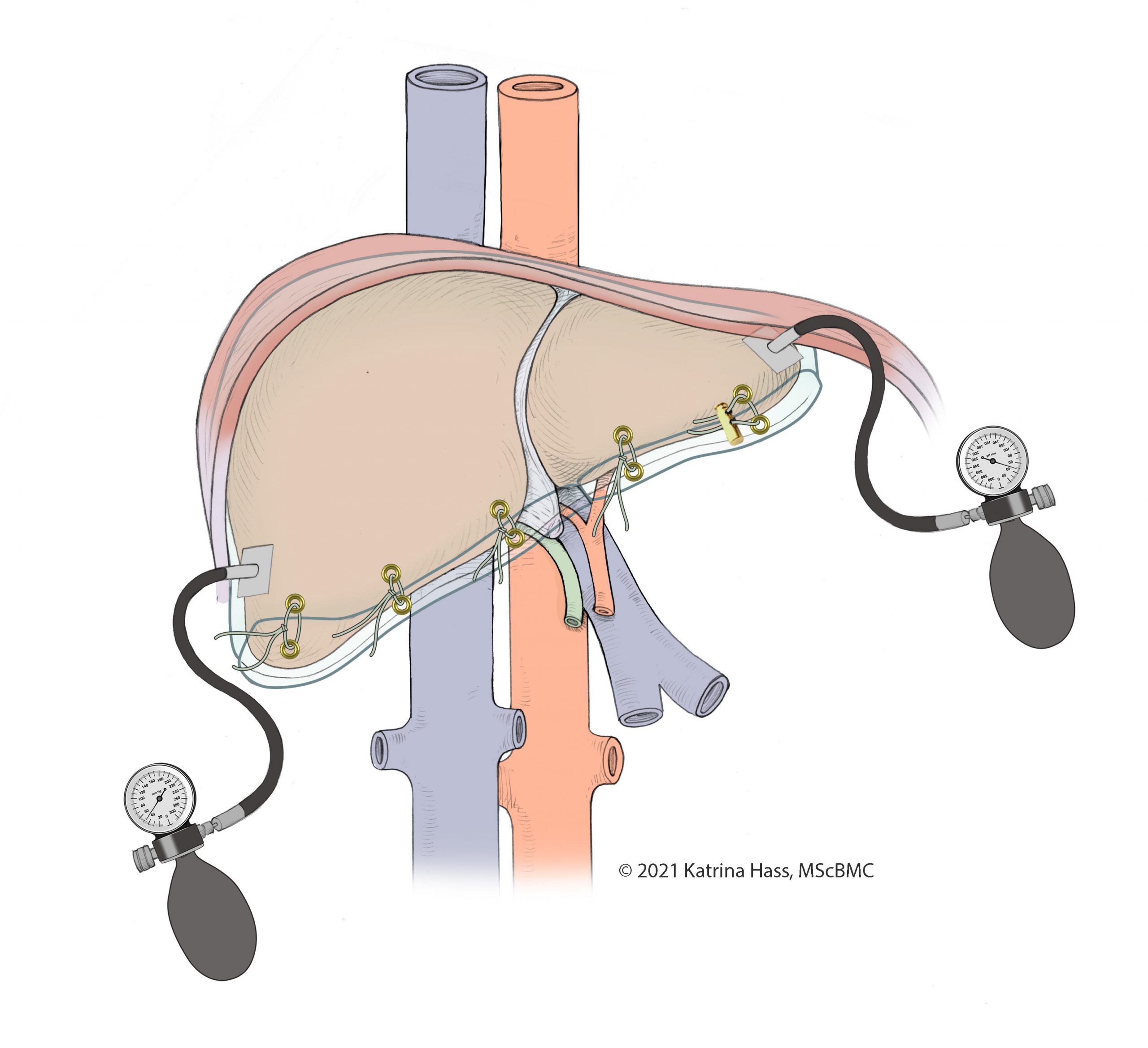

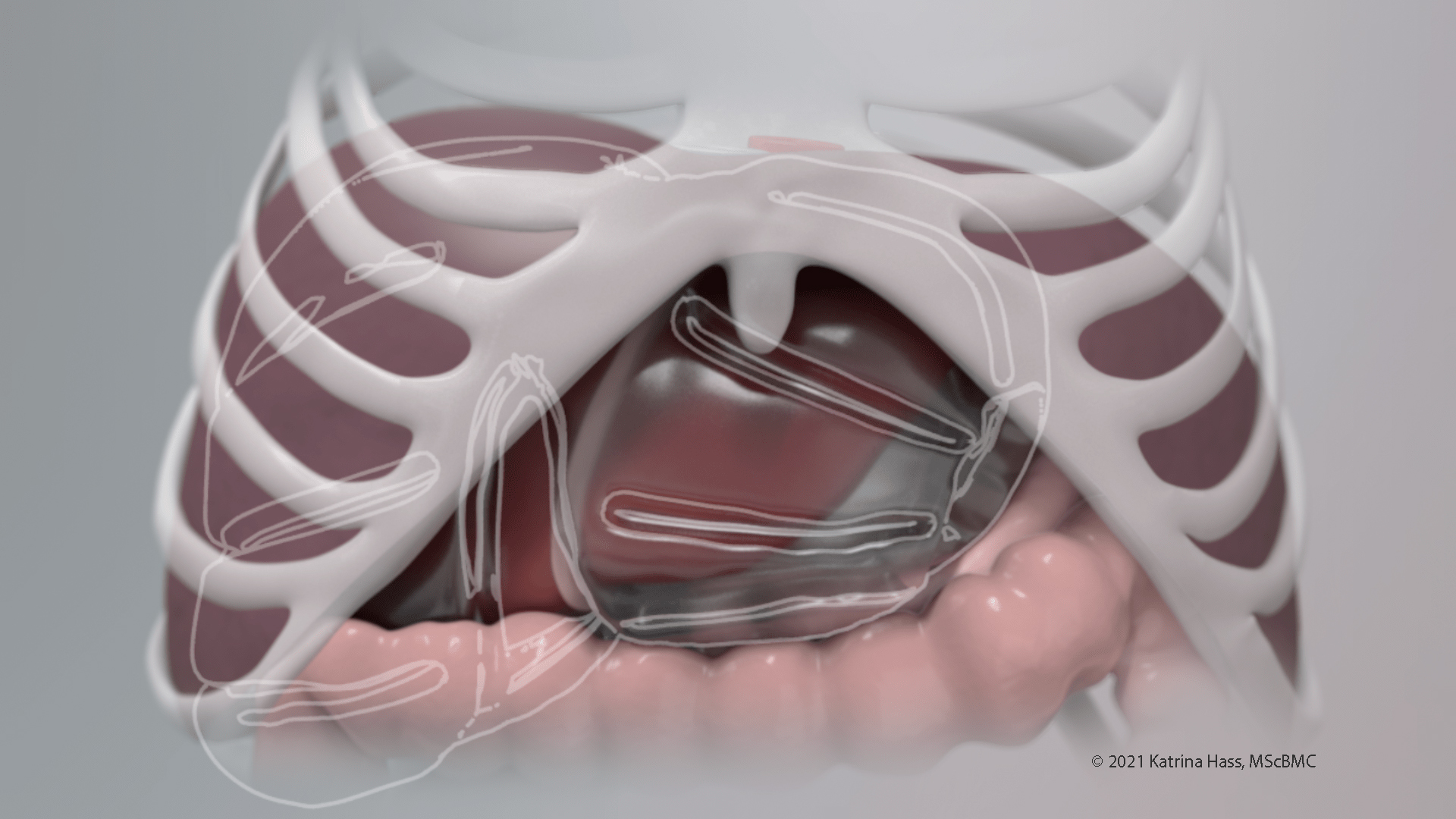

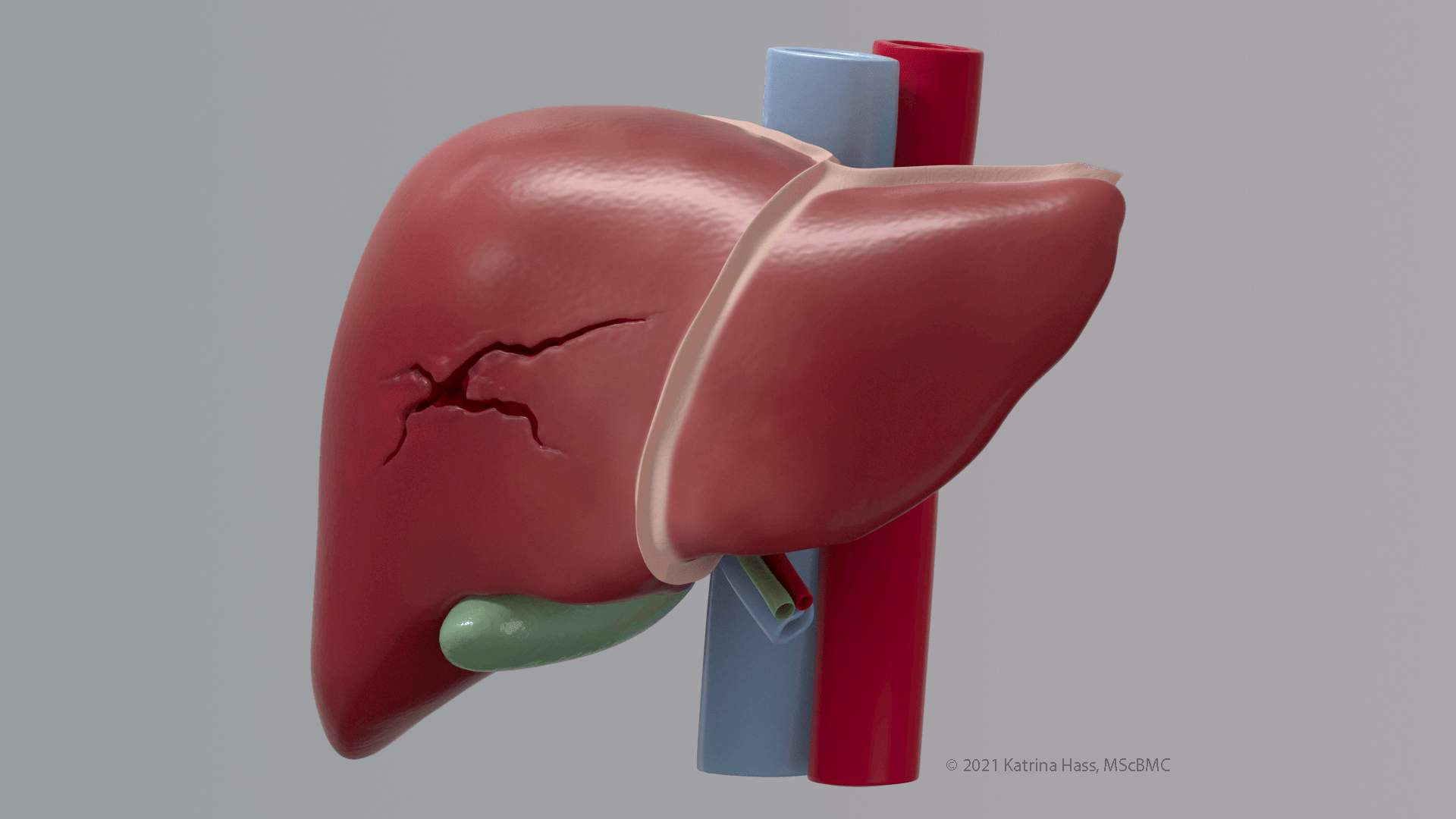

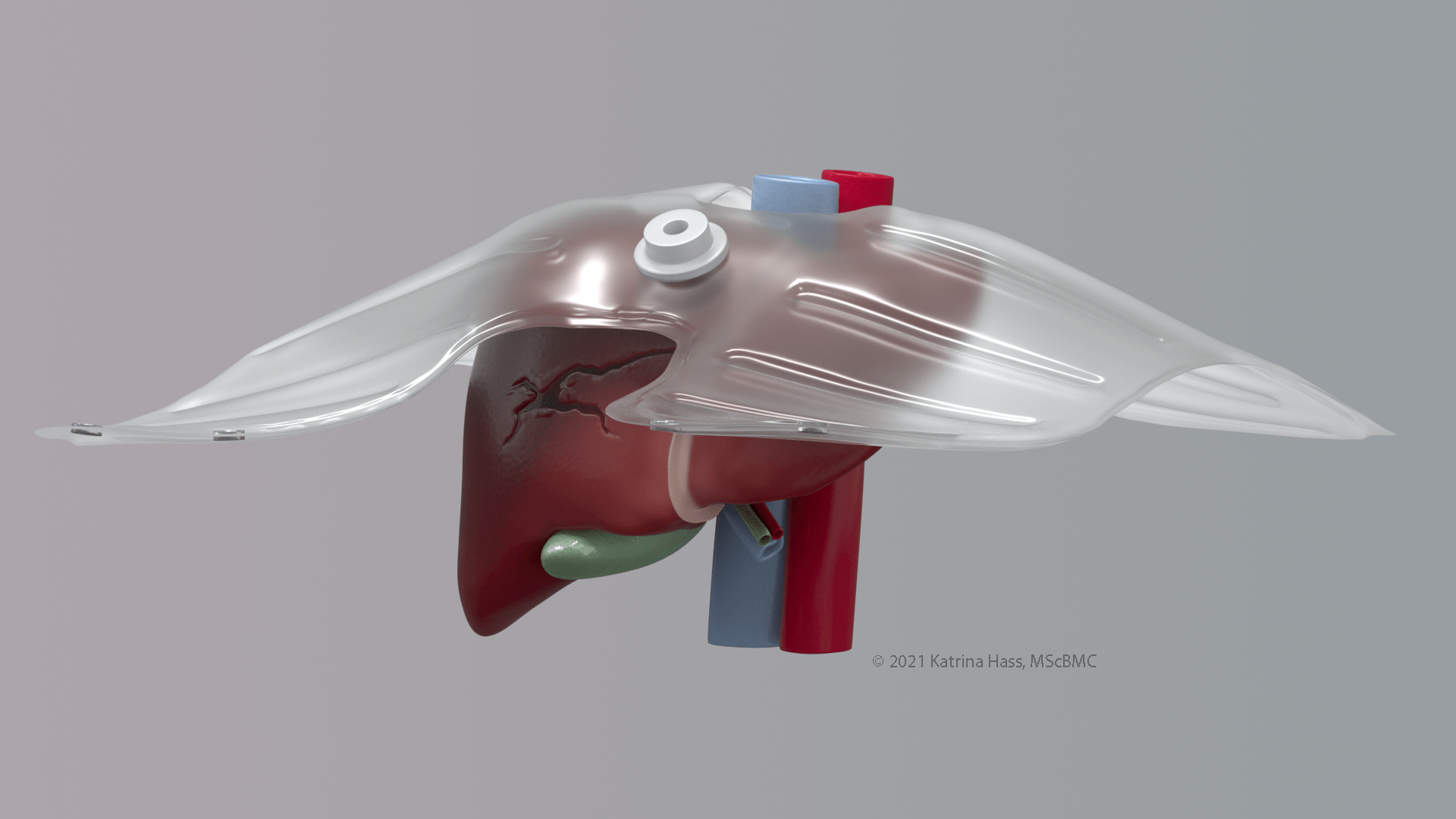

For my MRP (Masters Research Project), I worked with a trauma surgeon, Dr. Rezende-Neto, in developing a 3D animation for his new surgical invention, known as the Liver Airbag. This bag is intended to stop the bleeding in liver trauma patients. The objective of this project was to combine research from the fields of education and advertising in order to create an effective animation that would not only inform, but compel surgeons to action and to adopt the device.

These are the first concept illustrations I was introduced to for the liver airbag. This particular device would benefit from 3D animation as it is a complex product that requires an explanation of how it interacts with the surrounding anatomy. The fact that it is newly invented also calls for a visualization that could convince people that this device is useful.

The MRP was over a year-long process of research, script writing, storyboarding, 3D modelling, and animating.

Challenges

The most challenging aspect of this project was creating a 3D version of the liver airbag. There were two main challenges I encountered during this process:

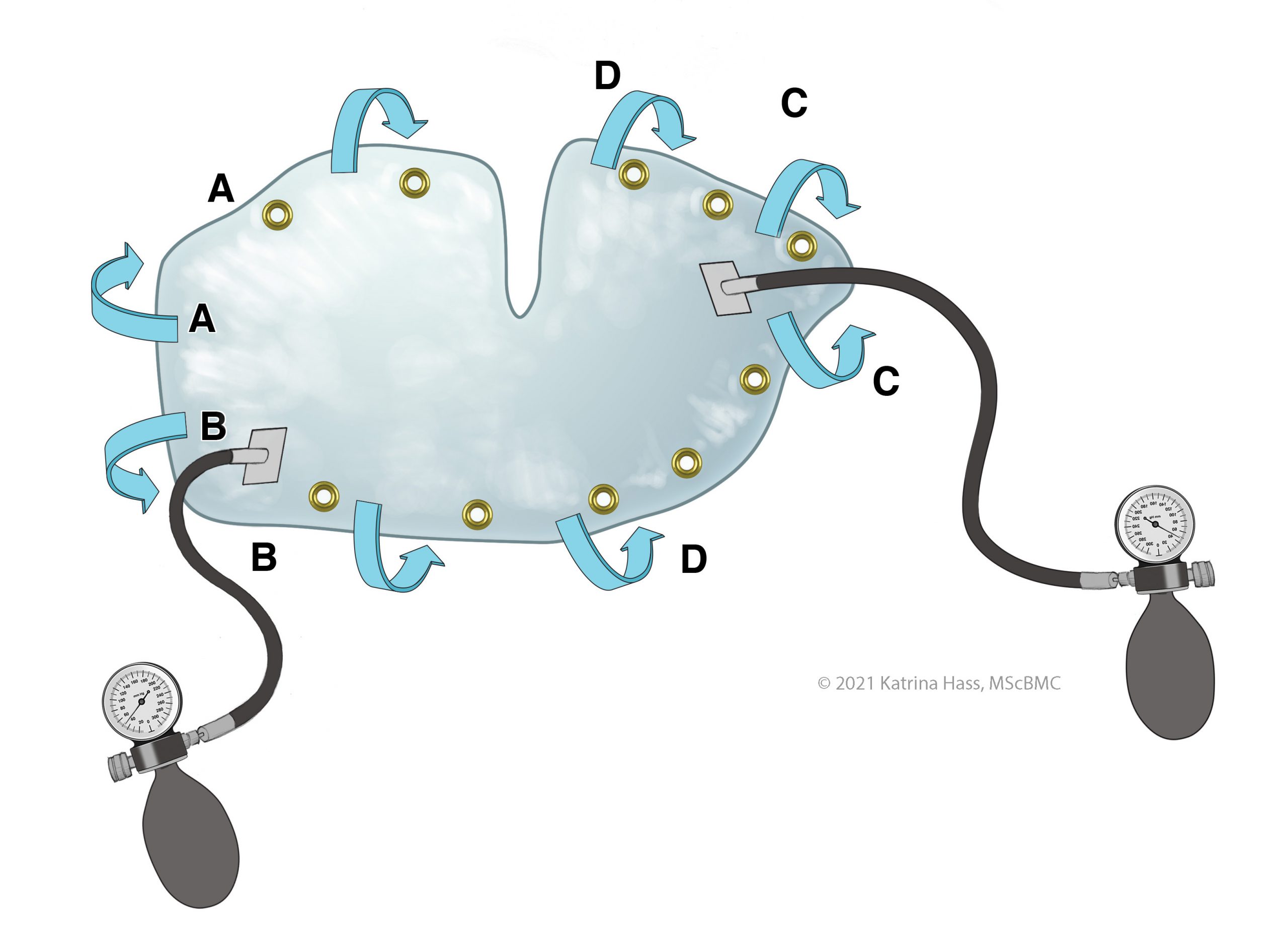

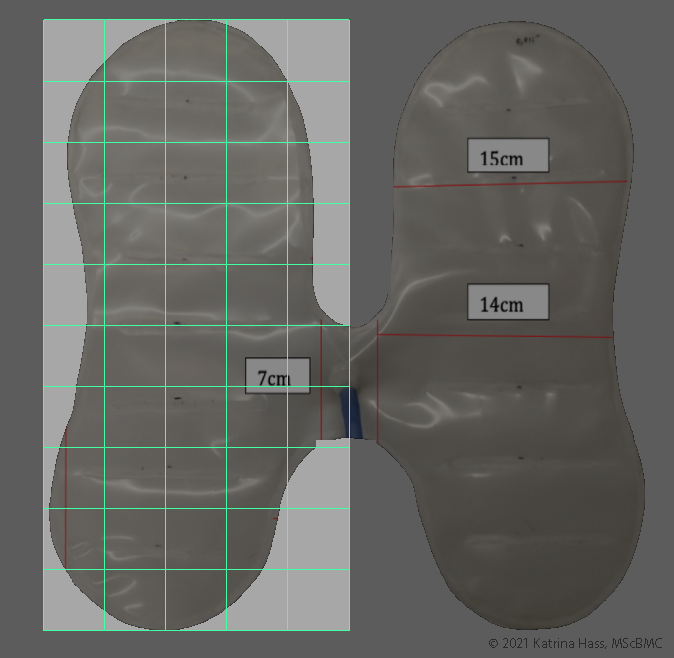

1) The first challenge was that the design of the liver airbag changed halfway through the process of 3D modelling.

Old Design

New Design

2) The second challenge was more technical. The model needed to do two things: i) wrap around the liver and ii) inflate around the liver.

These motions were difficult to animate realistically because of the odd and asymmetrical shape of the liver, and because the eyelets of the airbag needed to align perfectly for the airbag to be tied.

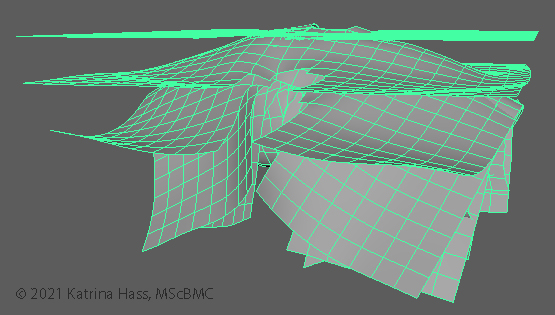

Many attempts were made including using a bend deformer and using a complicated joint system. The problems with these attempts were lack of control in the airbag’s motion and lack of fluidity. The final solution was to combine two techniques:

● First, a MASH blend deformer was applied to the model which simulated the inflation of the airbag.

● Next, I used a simple plane in the rough form of the liver airbag and turned it into an nCloth so that it could simulate the motion of falling realistically over the liver. I then duplicated various points in this simulation. These would be used to drive the blend shape deformation of the airbag. Essentially, the airbag model would follow the shape of these planes. The great thing about this was that these duplications could also be individually edited later on and the entire wrapping motion would still work (no need to start over!).

The final product was a model that was dynamic and could be easily controlled. The best part being that it could be edited in the future if any more challenges arose.

Experience Collaborating

Along with my MRP supervisors, Prof. Marc Dryer and Prof. Michael Corrin, I worked with Dr. Rezende-Neto to bring his invention to life virtually through 3D animation. As a biomedical communicator, my job was to make sure I fully understood his ideas and to find a way to translate them into something visual.

It was interesting to hear the unique perspective of a surgeon and how he approached designing an invention for success. For the purpose of this 3D animation, I had to combine his ideas with the perspective of an audience seeing a new invention for the first time. In reality, the process of using the liver airbag is more complicated than what is shown in this particular MRP video. However, we chose to show this process as something more refined and easy to understand. This way, the audience is informed about the invention and its process in a video that is short, concise, and effective in compelling them to learn more about the device.

I really enjoyed learning from Dr. Rezende-Neto and I am honoured to be a part of his project that could help save lives in the future.

-Katrina Hass, MScBMC

Dr. Rezende Neto was also kind enough to share with us some of his reflections on working with Katrina:

I was approached by Katrina and her supervisor Prof. Marc Dyer for this project several months ago. Although I have developed and patented several medical devices, this was the first time that I worked with a biomedical communicator. I was impressed with Ms. Hass knowledge of anatomy and how she was able to translate the idea and the mechanism of the Liver Airbag into the video. We had several meetings until the final version of the video was ready. During those meetings we provided feedback to Ms. Hass so she could develop the film. I must say that her questions also helped me address important aspects of the technology and improve the peer reviewed article recently published (Rezende-Neto J, Doshi S, Gomez D, Camilotti B, Marcuzzi D, Beckett A. A novel inflatable device for perihepatic packing and hepatic hemorrhage control: a proof-of-concept study. INJURY 2022; 53(1):103-111).

Ms. Hass organizational skills and determination are to be commended. She directly managed and hosted all meetings flawlessly. During those encounters we addressed all concerns and set up plans for upcoming meetings. All preliminary revisions of the video were addressed timely by Ms. Hass.

Undoubtedly, this experience has demonstrated that the knowledge of a biomedical communicator plays a major positive role in medical device development. That role extends beyond the artwork, it contributes to the actual mechanism and function of the device.

It was a privilege to have worked with Katrina Hass in this project.

Dr. Joao B. Rezende Neto MD, PhD, FRCSC, FACS

Trauma and Acute Care Surgery, General Surgery

St. Michael's Hospital

Professor Department of Surgery, University of Toronto

Associate Scientist, Keenan Research Centre

Lead for Device Development and Entrepreneurship

joao.rezende-neto@unityhealth.to

What a fascinating surgical innovation!

We hope you've enjoyed this overview of the production process for Katrina's Master Research Project. If you'd like to learn more about her work you can visit her website at khassvisuals.com or you can follow her on Twitter! Great work Katrina!!

--TVASurg Team